So how does it work?

1. First we prepare the item. Then after preparation, the base coat colour is applied, which is key to a quality finish.

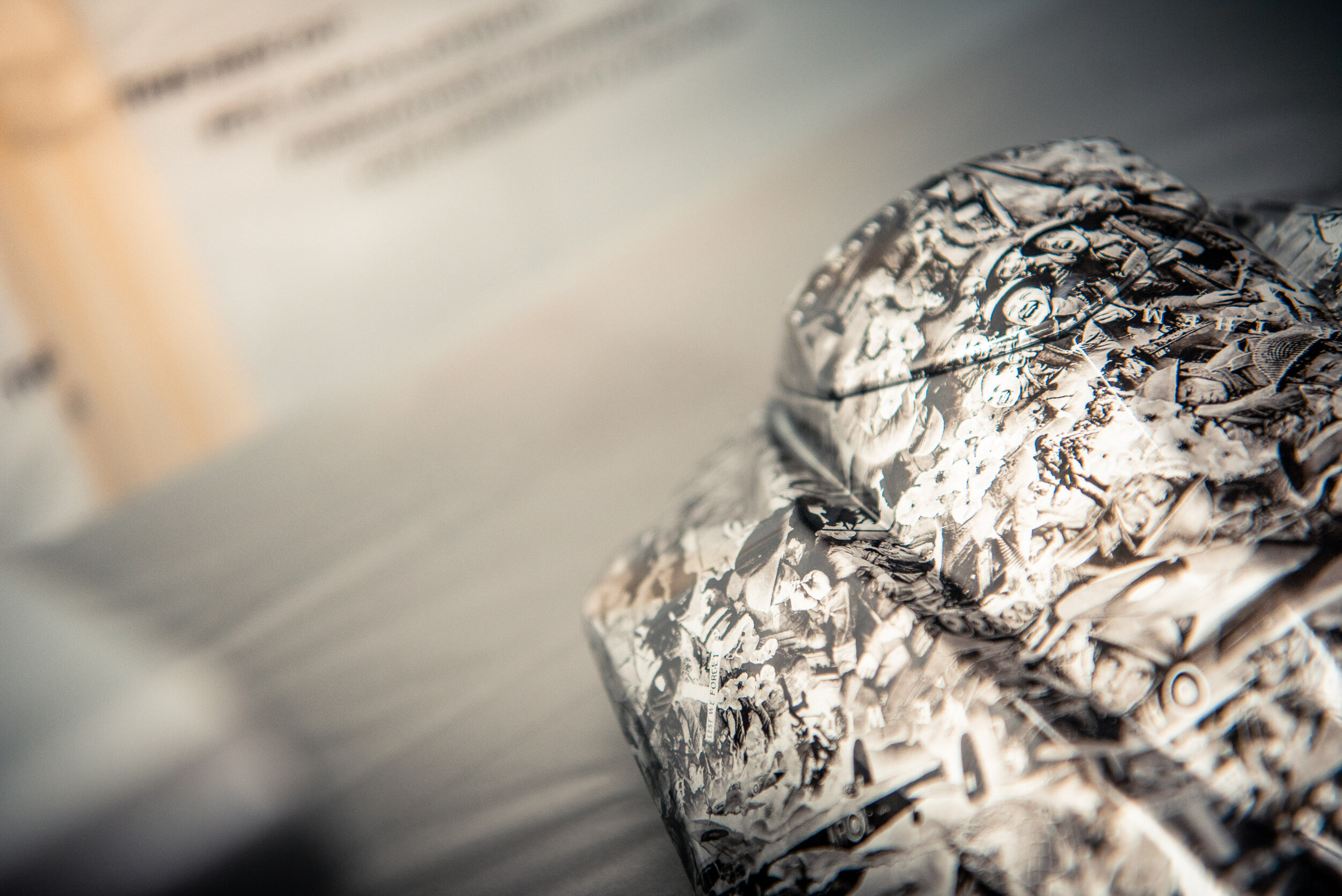

2. A polyvinyl alcohol film (PVA) is printed with your chosen print to be transferred, and is then floated on the surface of a large water tank.

3. An activator chemical is sprayed on the film to dissolve it into a liquid and activate a bonding agent.

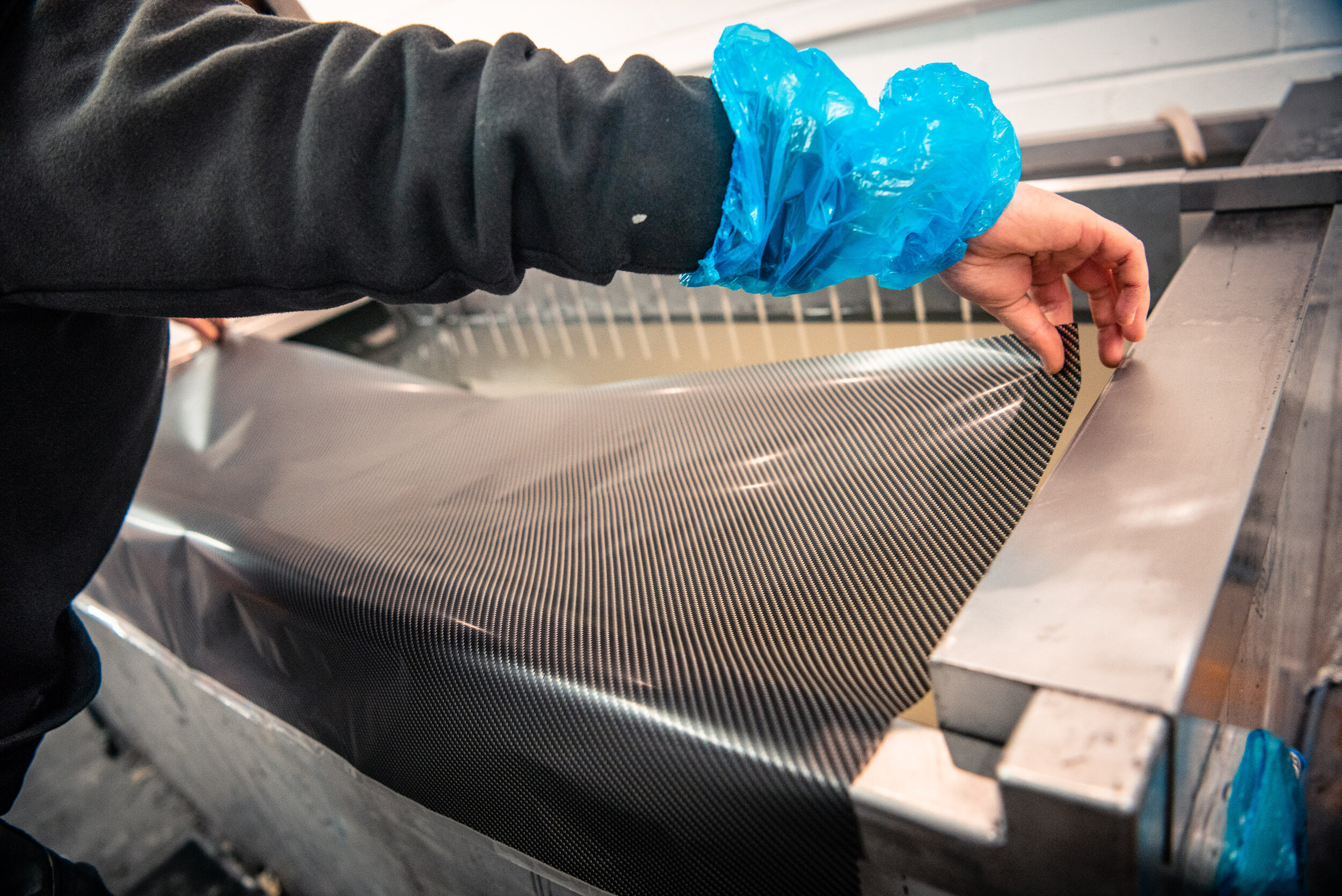

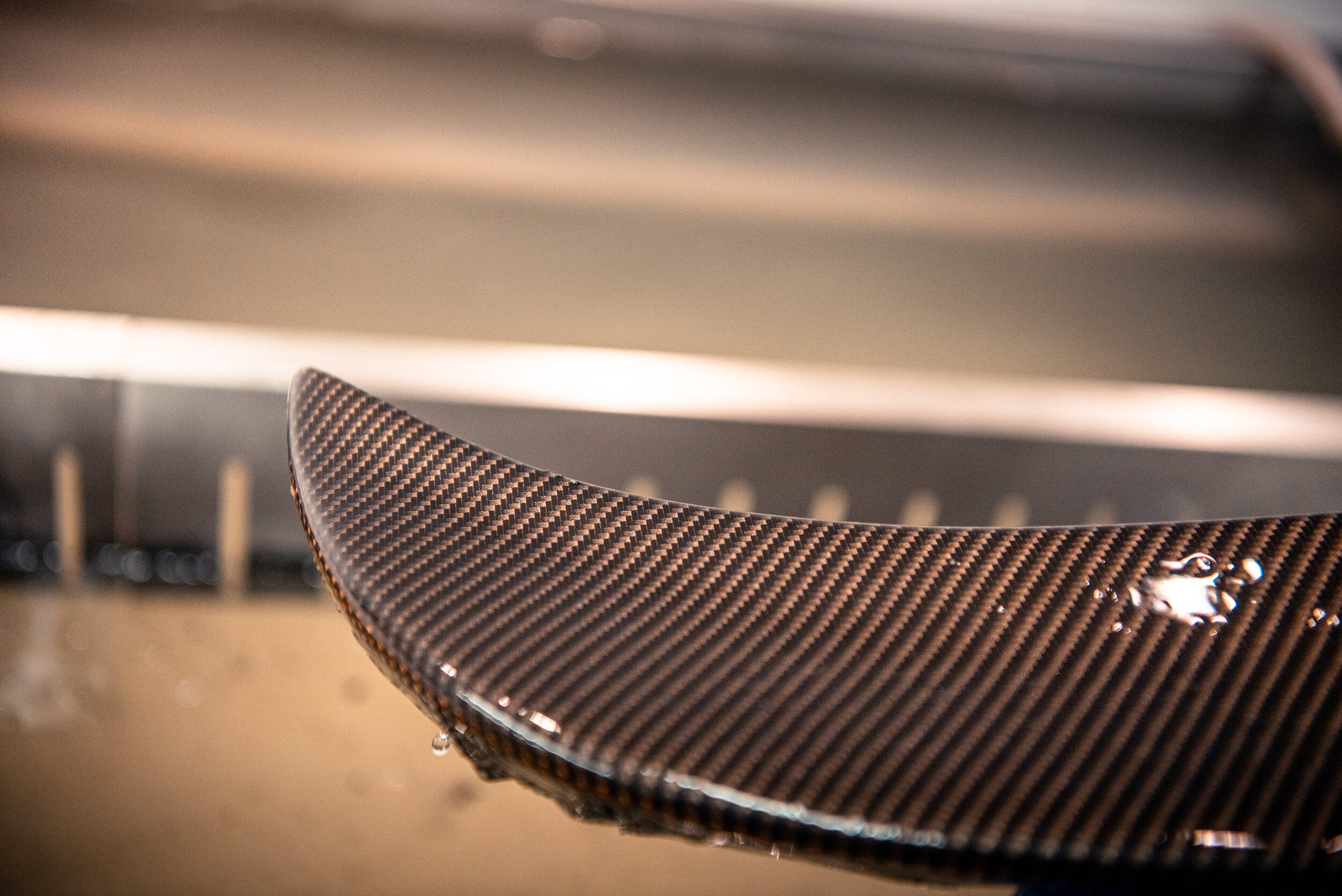

4. The piece is then lowered into the tank through the floating ink layer. The ink layer along with the polyvinyl alcohol backing then wraps around and adheres to the object. The adhesion is a result of the chemical components of the activator softening the base coat layer and allowing the ink to form a bond with it.

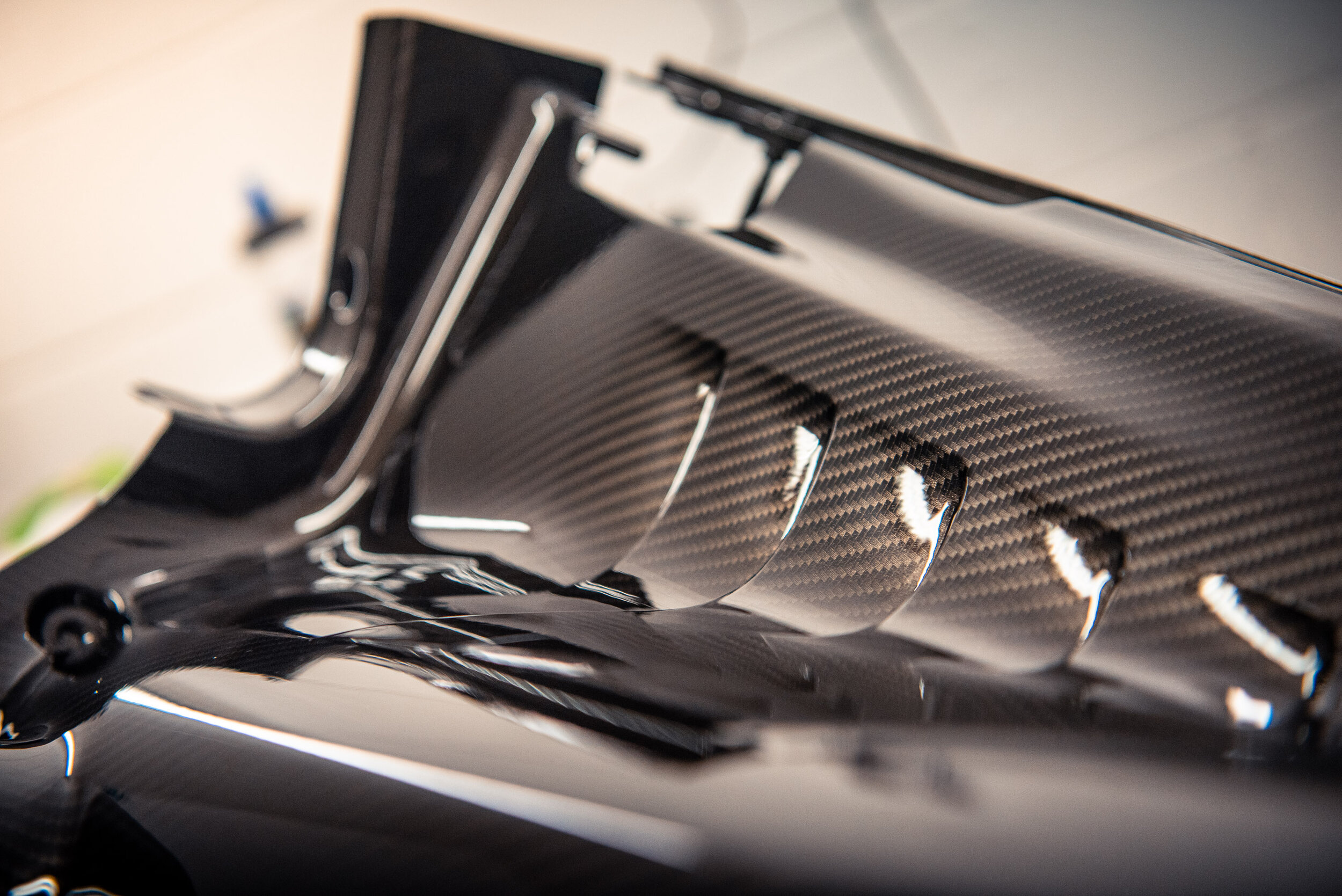

5. After removing the piece from the water, the object is washed, dried, lacquered and polished. This protects the dip as well as achieving the desired gloss level.

Let’s get your project going